Huigao polymer anti cracking mortar is made of high-strength ordinary silicon cement, high-quality quartz silica sand, various polymer materials, and anti cracking fibers and other functional additives.

POLYMER CRACK RESISTANT PLASTER MORTAR

Product features

scope of application

Adhesive and plastering of exterior wall insulation board

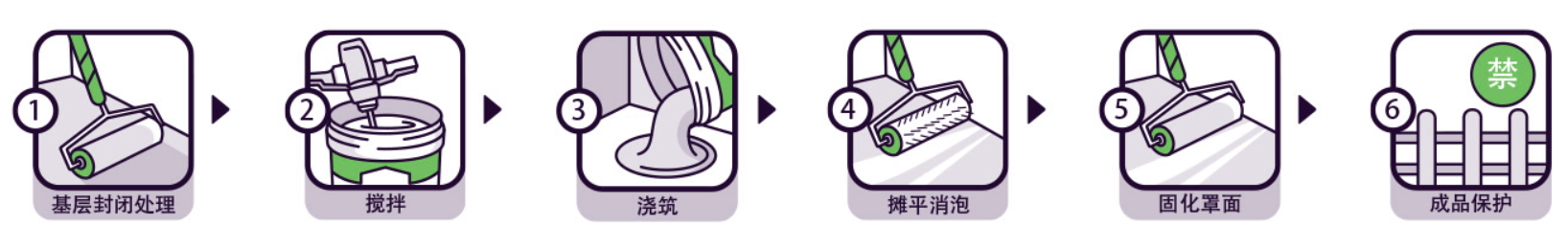

Usage | 1. Base treatment: Clean the dust, oil stains, and debris that affect the bonding performance of the wall surface. The base should be strong and free of hollowing. 2. Configure bonding mortar: The mass ratio of crack resistant mortar to water is 4:1 (weight ratio), and use an electric mixer to mix thoroughly without lumps. Let it stand for 5 to 10 minutes before & nbsp;& nbsp;& nbsp;& nbsp;& nbsp; Just mix it a little and it can be used. The mixed mortar should be used up within two hours. It is strictly prohibited to mix the solidified mortar again and put it into use. |

keep in storage | This product should be stored in a cool and ventilated place at 5-35 ° C to avoid rainy construction. The standard storage period is 6 months. |

Precautions | 1. In winter construction, anti freeze cracking mortar should be used. 2. Mix the mortar with a mixer and use it as you mix. When the weather is hot and the mortar dries quickly, adjust the mortar consistency appropriately. The product is stored more strictly in the transport machine. 3. The construction water must be pure tap water. 4. The transportation of this product shall be handled in accordance with the "Regulations for the Transport of Non Dangerous Goods". |

Execution standards | Technical standards: JC/T483-2015 & nbsp;& nbsp;& nbsp; Environmental standards: GB/T29906-2013 & nbsp;& nbsp; |

1. Easy to construct, ready for on-site mixing and use

2. High bonding strength

3. Fast hardening speed and strong crack resistance

4. Suitable for walls in various locations